Williams Metals and Welding Alloys, Inc.

Williams Metals and Welding Alloys, Inc.Request A Quote

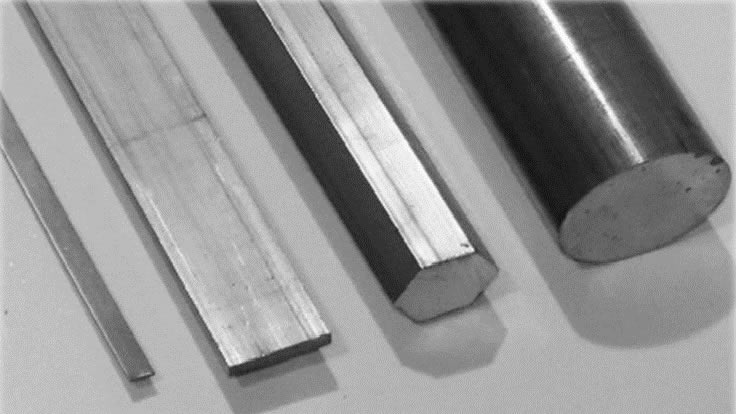

Wayne, PAWilliams Metals and Welding Alloys, Inc. stands as a pioneering force in the metallurgical and welding industry, headquartered in Wayne, Pennsylvania. With a rich legacy dating back several decades, the company has consistently evolved to become a leading provider of high-quality aluminum products and cutting-edge welding solutions. Mission Statement: At Williams Metals and Welding Alloys, our mission is to deliver unparalleled excellence in the field of metallurgy and welding. We are committed to providing our clients with top-tier aluminum products, backed by innovative welding solutions, while maintaining a steadfast focus on quality, reliability, and customer satisfaction. Product Portfolio: Aluminum Alloys: Williams Metals and Welding Alloys specializes in a comprehensive range of aluminum alloys, catering to diverse industrial needs. Our aluminum products boast exceptional strength, corrosion resistance, and versatility, making them ideal for applications across various sectors, including aerospace, automotive, construction, and more. Custom Aluminum Fabrication: In addition to offering a wide spectrum of standard aluminum products, our company takes pride in its custom aluminum fabrication capabilities. Our skilled team of metallurgists and fabricators collaborates closely with clients to design and manufacture tailor-made aluminum components that meet specific project requirements. Aluminum Welding Solutions: Williams Metals and Welding Alloys is renowned for its advanced welding solutions tailored to aluminum alloys. Our welding processes ensure the integrity and longevity of aluminum structures, guaranteeing precision and reliability. We employ state-of-the-art technologies and adhere to industry best practices to deliver welding services that exceed expectations. Service Capabilities: Technical Expertise: Our team of metallurgical experts and engineers possesses extensive knowledge and expertise in aluminum metallurgy. This enables us to provide clients with in-depth technical support, ensuring the optimal selection of aluminum alloys for their unique applications. Responsive Customer Service: Williams Metals and Welding Alloys is committed to delivering exceptional customer service. Our responsive and knowledgeable team is always ready to assist clients with product inquiries, technical questions, and any other assistance required to facilitate smooth and successful projects. Quality Assurance: Quality is at the core of everything we do. Our commitment to maintaining the highest standards in product quality is reflected in our ISO-certified processes. Rigorous quality control measures are implemented at every stage of production, ensuring that our aluminum products meet or exceed industry specifications. Logistics and Timely Delivery: Recognizing the importance of timely project completion, we have established a robust logistics network to ensure prompt and efficient delivery of our aluminum products to clients across the region. In conclusion, Williams Metals and Welding Alloys, Inc. is more than a supplier; it is a reliable partner for businesses seeking top-tier aluminum products and welding solutions. With a focus on innovation, quality, and customer satisfaction, we continue to shape the future of the metallurgical and welding industry.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services