Time is money, and we save you both. We don’t mess around when it comes to precious time, and we offer the highest quality aluminum products that other companies don’t stock. We make a point of keeping products on-hand that other companies will not, because it is our goal to make your experience with us painless and fulfilling. Visit our website or call us today to learn more!

At CBC Specialty Metals & Processing, we pride ourselves on being a leading provider of high-quality aluminum products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in aluminum distribution and processing, renowned for our commitment to excellence,...

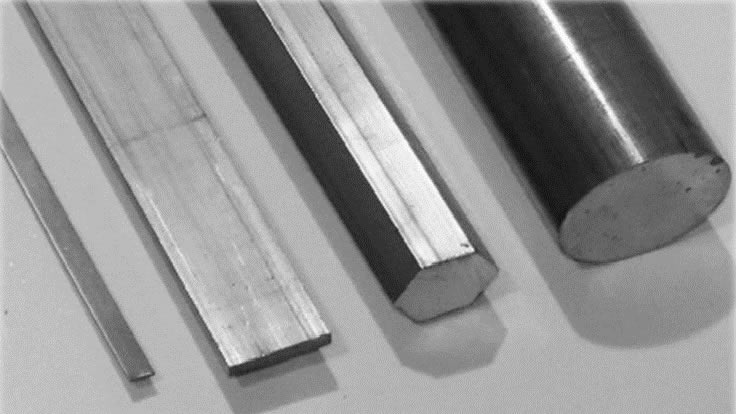

Since 1923, EMJ has been a leading supplier of Steel and Aluminum Bar, Tubing, and Plate to manufacturing companies in North America. Our broad network of facilities, superior inventories, processing capabilities, and world-class technology enables EMJ to provide unsurpassed service to our customers.

At Triple-S Steel Holdings, Inc., we take pride in our position as a leading provider of high-quality aluminum products and comprehensive solutions tailored to meet the diverse needs of our clientele. With decades of experience and dedication to excellence, we have established ourselves as a trusted name in the aluminum industry, renowned for our commitment to quality, reliability, and customer...

More Aluminum Coil Manufacturers

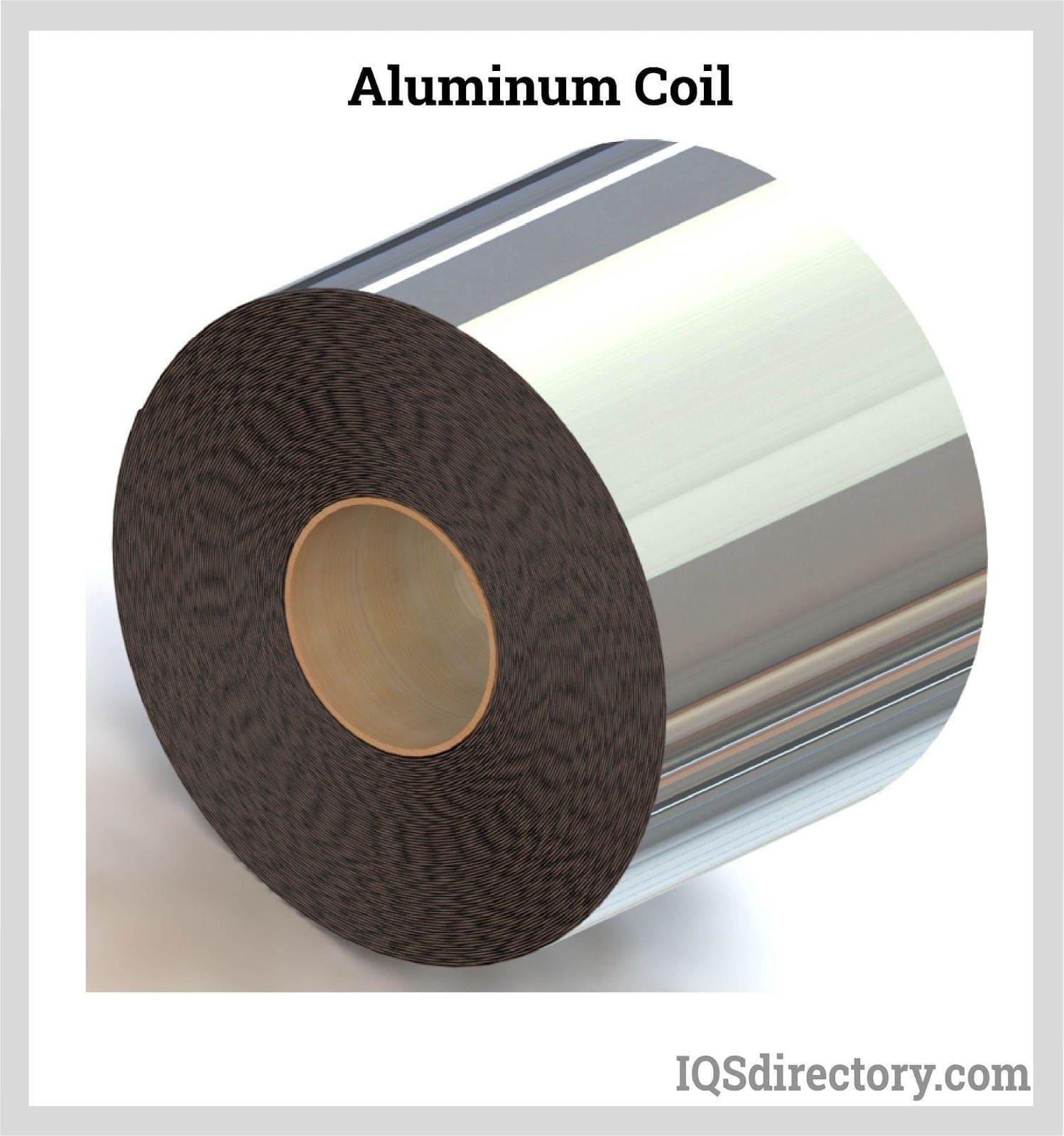

A procedure known as cold rolling or direct casting can be used to create an aluminum coil from aluminum ingots or other types of raw aluminum, or rolling can be used to create it immediately from the smelting process (called a continuous cast). Then, these aluminum sheets are coiled or rolled up around a core. Compared to aluminum sheets, these coils are more densely packed, making them simpler to ship and store. In addition, a virtually infinite variety of components utilized in various industries are produced using the coil.

For the majority of manufacturing uses, pure aluminum is too soft. As a result, most aluminum coils are produced and delivered as an alloy. These alloys contain two or more elements, at least one of which is aluminum. The Aluminum Association oversees the four-digit number system to identify aluminum alloys for sheet products. Aluminium’s mechanical and other qualities can be adjusted to satisfy particular demands for strength, formability, and other properties when alloyed with other metals.

Aluminum coil, often known as "gauge," is offered in different lengths, widths, and thicknesses. The size of the components created and the production technique employed define the precise dimensions. In addition, many surface treatments are available, such as mill, matte, and brilliant. The choice will be based on the intended purpose and appearance of the finished component.

Also available in a variety of tempers is the aluminum coil. "F" temper, which has no set mechanical restrictions and no specific control over the thermal or work-hardening conditions has been applied, may be offered "as manufactured." This method is typically utilized for products in the middle of the production process because it is variable. Another choice pertains to wrought items strengthened by cold-rolling or cold-working, known as strain-hardened. The metal can also be annealed, which means it has to go through a controlled heating process to achieve the ideal balance of strength and formability.

Characteristics of Aluminum Coil

Non-Corrosive:

Aluminum is incredibly resistant to weathering and corrosion, even in industrial settings where other metals are routinely damaged. For example, it won't rust when exposed to various acids. In addition, aluminum has remarkable corrosion resistance because it naturally produces a thin but effective oxide coating that prevents further oxidation. As a result, numerous corrosive chemicals rarely penetrate items constructed of aluminum oxide.

Easily Machined and Cast:

Aluminum coil is more malleable and easier to pour into molds because it melts faster than steel. Aluminum castings are also less difficult to work with than steel castings, which require a lot more effort because they are less rigid than steel castings. In addition, it is one of the most machinable metals, reducing the processing time cost.

Non-Magnetic and Non-Sparking:

Aluminium’s crystalline structure prevents it from being magnetic. As a result, any scrape causes an oxide layer to grow quickly, preventing sparking.

Pliable:

Because free electrons are available for bonding, aluminum coils are pliable.

Non-Toxic:

Exposure to aluminum is not harmful to the body.

Malleable:

The coils are easier to shape since aluminum is more malleable than the bulk of other metals. The greater flexibility allows engineers to bend coils into functional designs. For instance, microchannel coils increase corrosion resistance, reduce leaks, and improve heat transfer.

Ductile:

In addition to being lightweight and non-toxic, and having high thermal conductivity and great corrosion resistance, aluminum is also simple to cast, mill, and form. Additionally, it is neither magnetic nor sparking. It is the second-most malleable metal and has a high degree of ductility, making it ideal for making wire from this substance.

Reasons for Choosing Aluminum

- Weight – The primary benefit of aluminum over most competing materials is its reduced weight. This reduced weight makes it perfect for industries like automotive and aerospace, where total product weight is a consideration. Additionally, shipping costs are lower as a result.

- Workability - Because aluminum is so flexible, it can be easily molded, stamped, or otherwise shaped. Its popularity is primarily influenced by its usability and adaptability. As a result, many production procedures favor aluminum, including drawing, roll forming, and stamping.

- Value – Aluminum is significantly less expensive than materials like copper, which enables producers to reduce material prices without compromising performance.

- Recyclability – Aluminum is easily recycled and can be reused repeatedly, minimizing its negative environmental effects.

- Conductive Properties – Aluminum coils' structure, which contains free electrons, makes them effective electrical conductors. In addition, the aluminum coil is an excellent conductor of heat because there is a constant flow of these electrons. Electrical grade aluminum has a conductivity of 62% of electrical grade copper as measured by equal cross-sectional area. But when the two materials are weighed the same, copper has a conductivity of 204%.

Uses of Aluminum Coil

There are numerous uses and industries for the coil. Many stamped and molded components in electronics, medicine, transportation, and other industries use it as their preferred material.

Transportation: It is extensively employed for transportation, as was already indicated. It is utilized in the auto industry to create anything from radiators and wheel hubs to engine parts and automobile doors. Using aluminum to substitute heavier metals can significantly reduce vehicle weight as the automotive industry works to do so. The term "lightweighting” represents optimizing all components to have the lowest weight.

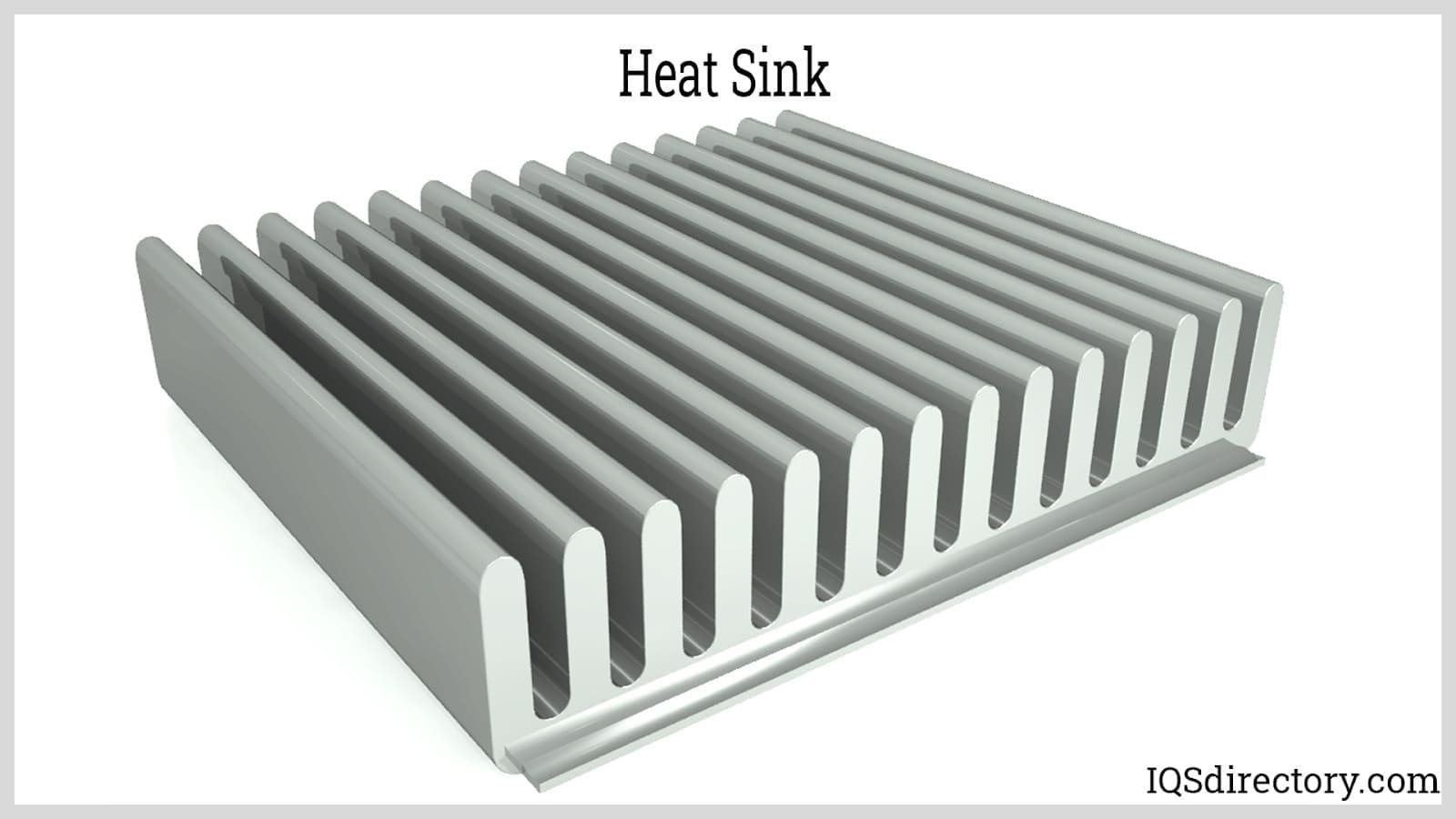

Electronics: Aluminum is used in many industrial and consumer electronics because metal is an excellent conductor of electricity, retains heat, and is corrosion-resistant. Heat sinks, stamped components, shielding, and bigger components, like enclosures, can all be produced using it.

Consumer Goods and Hardware: Packaging for health and beauty products, tools and other hardware, building applications, jewelry, and a huge variety of other common objects all use aluminum parts made from aluminum coil.

Medical: Aluminum is widely used in the medical and dental fields for many products ranging from disposables to surgical equipment and sophisticated electronic devices.

Aerospace: Some aluminum alloys and tempers are perfect for aerospace applications due to their small weight, ability to resist corrosion, and potential for strength.

Choosing the Right Aluminium Coils Company

To make sure you have the most positive outcome when purchasing Aluminium Coils from an Aluminium Coils Manufacturer, it is important to compare at least 5 or 6 Companies using our list of Aluminium Coils suppliers. Each Aluminium Coils Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Aluminium Coils company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Aluminium Coils businesses with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services