Time is money, and we save you both. We don’t mess around when it comes to precious time, and we offer the highest quality aluminum products that other companies don’t stock. We make a point of keeping products on-hand that other companies will not, because it is our goal to make your experience with us painless and fulfilling. Visit our website or call us today to learn more!

At CBC Specialty Metals & Processing, we pride ourselves on being a leading provider of high-quality aluminum products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in aluminum distribution and processing, renowned for our commitment to excellence,...

Since 1923, EMJ has been a leading supplier of Steel and Aluminum Bar, Tubing, and Plate to manufacturing companies in North America. Our broad network of facilities, superior inventories, processing capabilities, and world-class technology enables EMJ to provide unsurpassed service to our customers.

At Triple-S Steel Holdings, Inc., we take pride in our position as a leading provider of high-quality aluminum products and comprehensive solutions tailored to meet the diverse needs of our clientele. With decades of experience and dedication to excellence, we have established ourselves as a trusted name in the aluminum industry, renowned for our commitment to quality, reliability, and customer...

More Aluminum Manufacturers

Aluminum, a remarkably versatile and indispensable metal, has transformed modern society with its unique attributes. Its influence spans a wide range of fields, from transportation and construction to packaging and consumer goods. Although Danish chemist Hans Christian Oersted first produced aluminum in 1825, it wasn’t until the 1880s that the metal became commercially feasible. This breakthrough came with the development of the Hall-Heroult process, an innovative method for extracting aluminum from its ore. This process revolutionized the industry, making aluminum more accessible and cost-effective, which paved the way for its extensive use today.

Processes for Creating Aluminum

Aluminum is abundant in the earth’s crust, yet it never appears in its pure form naturally. They extract it from bauxite, a reddish-brown rock rich in aluminum oxide. The primary method for producing aluminum is the Hall-Heroult process, which consists of two main stages: first, refining bauxite into alumina, and second, processing the alumina through an electrolytic cell to obtain pure aluminum.

They crush bauxite ore into small pieces and then heat it in a kiln to produce alumina, a white powder. They dissolve the alumina in molten cryolite, a mineral used as a solvent, and feed it into an electrolytic cell. Inside the cell, they pass an electric current through the molten mixture, which causes the aluminum ions to separate from the oxygen and collect at the cathode. The oxygen then combines with the carbon anode to form carbon dioxide, which is released as a gas. They cool and shape the collected aluminum into desired products.

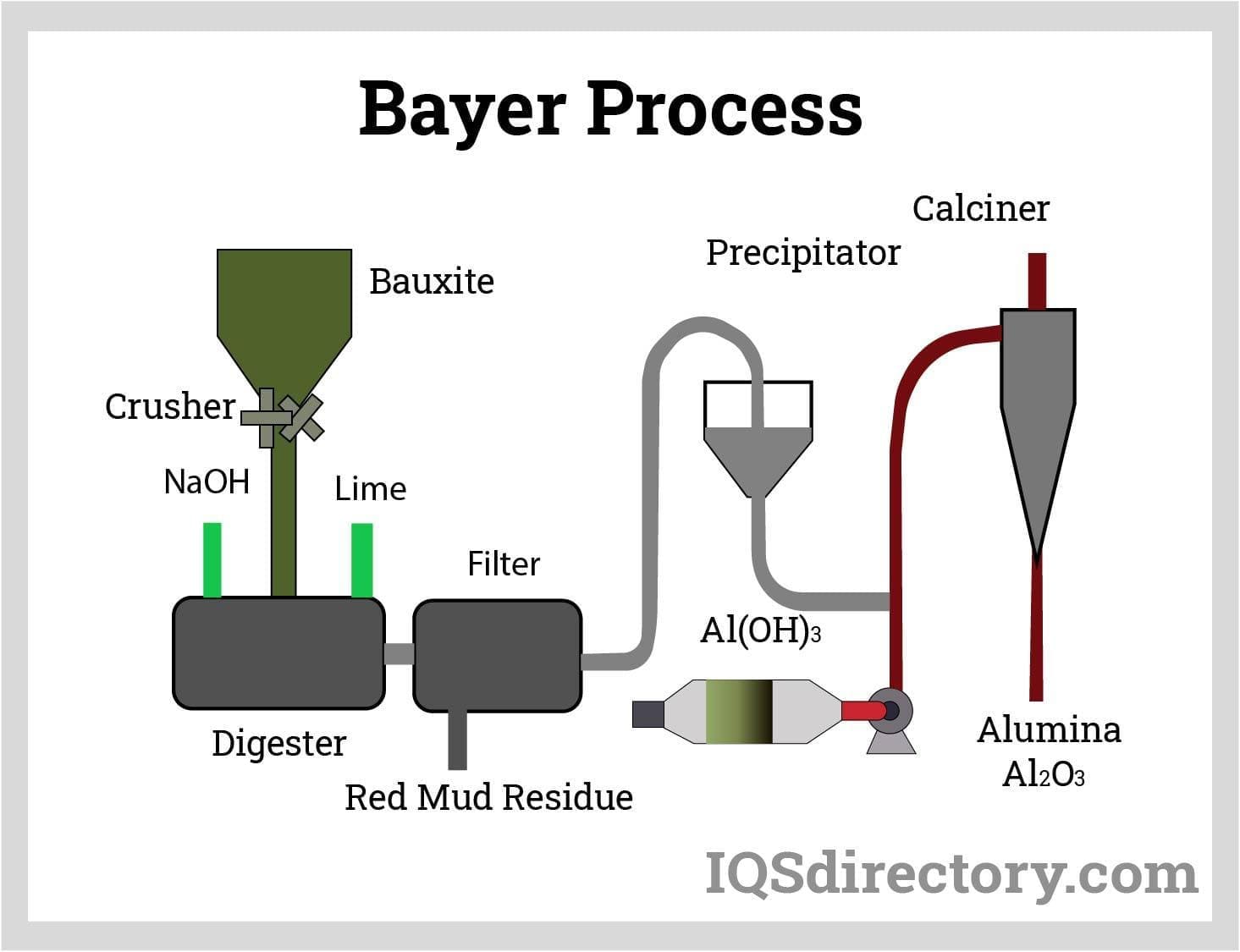

Another method for producing aluminum is the Bayer process. This technique starts by grinding bauxite into a fine powder, which is then mixed with hot caustic soda, a powerful alkali solution. The resulting mixture is filtered and washed to eliminate impurities, resulting in pure alumina.

In secondary aluminum production, they recycle scrap aluminum by melting it down to create new products. This method, called remelting or recycling, involves heating scrap aluminum in a furnace, blending it with other metals to form alloys, and then casting it into fresh items. This approach uses less energy and generates fewer emissions compared to primary production, making it a more sustainable choice.

Disadvantages of Aluminum

The process of producing aluminum significantly impacts the environment, contributing to air pollution, greenhouse gas emissions, and the destruction of natural habitats. In addition to these effects, exposure to aluminum has been associated with health risks such as respiratory issues and neurological disorders. Moreover, managing aluminum waste and recycling can be problematic, and improper disposal poses further environmental hazards.

Benefits of Aluminum

Aluminum offers a range of advantages that make it crucial to contemporary life. Let’s explore some of the additional benefits it brings:

Lightweight

Aluminum, a lightweight metal that weighs roughly one-third as much as steel, proves to be an excellent choice for transportation. Its reduced weight translates to lower fuel consumption and emissions, making it a more eco-friendly option.

Corrosion-Resistant

Aluminum boasts impressive corrosion resistance, which makes it ideal for outdoor uses like building facades and roofing. Its durability extends to marine environments and food and beverage containers, where its resistance to corrosion is crucial.

Durable

Aluminum boasts remarkable durability, effortlessly enduring extreme temperatures, which makes it perfectly suited for demanding high-temperature applications like those in the aerospace sector. Its longevity is equally impressive, with a potential lifespan reaching up to a century.

Conductive

Aluminum excels at conducting heat and electricity, making it perfect for electrical and electronic applications. Its ability to rapidly dissipate heat also makes it an excellent choice for heat sinks and cooling systems.

Versatile

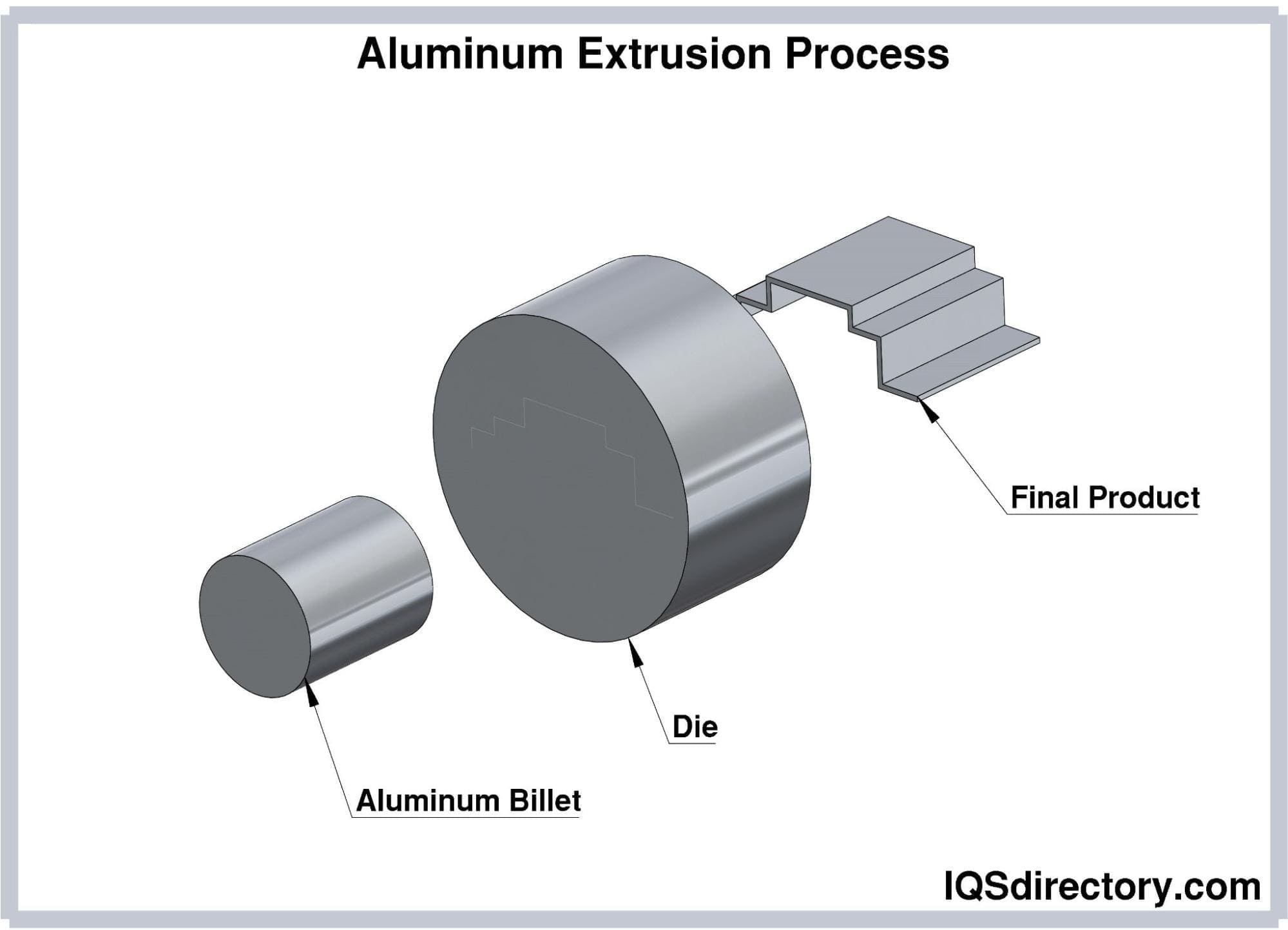

Aluminum offers incredible versatility, effortlessly adapting to various shapes and sizes. Its properties allow it to be cast, forged, extruded, or machined, making it a go-to choice for numerous applications.

Recyclable

Aluminum is an exceptionally recyclable material, with more than 75% of all aluminum ever produced still in use today. Recycling aluminum uses just 5% of the energy needed to create new aluminum.

Innovations in Aluminum Recycling

Recent years have seen a surge in innovations within aluminum recycling, fueled by a growing emphasis on sustainability and resource conservation. We’ve witnessed a range of technological advancements aimed at boosting the efficiency and effectiveness of recycling processes. Notably, one significant area of progress includes the development of sophisticated sorting methods, such as sensor-based systems and spectroscopic technologies, which allow for more accurate separation of aluminum from other materials in the recycling stream. Our advancements in recycling technology have significantly enhanced the purity and quality of recycled aluminum, making it suitable for a wider array of applications. We’ve incorporated innovative separation techniques—like hydrocyclones, eddy current separators, and electromagnetic sorting—to boost the efficiency of aluminum recovery from complex waste streams. These improvements also extend to energy efficiency and environmental impact, with cutting-edge smelting processes such as salt-free molten metal refining reducing both energy consumption and greenhouse gas emissions. Overall, these technological breakthroughs are vital for increasing recycling rates, lessening the reliance on primary aluminum production, and minimizing the environmental footprint of the aluminum industry.

Grades of Aluminum

There is a range of aluminum grades, each with unique characteristics and properties that suit various applications. The grading system for aluminum usually combines numerical digits and letters to identify different alloys and compositions. Here are some commonly used grades of aluminum:

1000 Series

This series is commonly known as pure aluminum and consists of nearly 99% aluminum. It is characterized by its softness, ductility, and outstanding corrosion resistance, though it falls short in strength compared to other alloy series. Its typical uses include electrical applications and chemical processing equipment.

2000 Series

These alloys boast an impressive strength-to-weight ratio and are mainly utilized in aerospace settings. The inclusion of copper as the key alloying component imparts remarkable strength and notable fatigue resistance. Nonetheless, they exhibit reduced corrosion resistance when compared to other grades.

3000 Series

This series, infused with manganese, boasts greater strength than pure aluminum, while retaining excellent formability and resistance to corrosion. It’s commonly utilized in a variety of general-purpose applications, including cooking utensils, heat exchangers, and food packaging.

5000 Series

These alloys feature magnesium as their main alloying element, delivering superb weldability, balanced strength, and strong corrosion resistance. We commonly use them in marine and architectural settings, as well as in vehicles and structural elements.

6000 Series

This series is widely favored for extrusions and structural applications. Alloys like 6061 and 6063 within this series offer excellent formability and weldability, alongside moderate strength. They are extensively employed in construction, automotive parts, and furniture.

7000 Series

The 7000 series alloys are celebrated for their impressive strength, making them ideal for aerospace and structural uses where superior strength-to-weight ratios are crucial. However, they are generally more challenging to shape and offer lower corrosion resistance compared to other grades.

We should remember that each grade of aluminum can have variations and unique alloy compositions designed for particular needs. Detailed specifications and guidelines from manufacturers and industry standards help us choose the right grade for our specific applications.

Selecting the Proper Aluminum Series

Selecting the right grade or series of aluminum for a particular application involves evaluating several key factors. You should start by assessing the mechanical properties needed, such as strength, hardness, ductility, and toughness. For applications that need high strength, the 2000 or 7000 series alloys might be appropriate. Conversely, if the application requires moderate strength along with good formability, the 6000 series alloys could be more beneficial.

Next, you need to think about the environmental conditions the aluminum will face. For corrosive environments, like those in marine or chemical settings, choosing an alloy with strong corrosion resistance, such as those from the 5000 or 6000 series, is wise. Conversely, if high temperatures are a factor, you should select an aluminum grade with good heat resistance.

Other factors for you to consider include the manufacturing process and the feasibility of forming the desired shapes or structures. Some alloys might be more suitable for specific manufacturing processes, such as extrusion, casting, or machining. Additionally, you should take into account factors like cost, availability, and the overall design requirements.

Working with material suppliers, engineers, or industry experts can greatly assist you in choosing the right grade of aluminum for your needs. Their expertise and insights can help you navigate the specific requirements and limitations of your application. You can also refer to industry standards and specifications from organizations like ASTM International or the Aluminum Association. By considering these factors and consulting with knowledgeable professionals, you can make a well-informed choice and select the most appropriate aluminum grade or series for your application.

Applications of Aluminum

Aluminum’s distinctive characteristics have made it an essential material across various industries. Let’s explore some of its specific applications.

Transportation

Aluminum frequently finds application in the transportation sector to lessen weight and enhance fuel efficiency. It’s utilized in the assembly of cars, trucks, and airplanes, and is also integral to bike frames, wheels, and various other components.

Packaging

Aluminum finds extensive use in packaging because of its lightness, resistance to corrosion, and recyclability. They use it in making beverage cans, food containers, and foil, as well as in various other applications.

Construction

They use aluminum in construction because of its strength, durability, and resistance to corrosion. It plays a key role in making doors, windows, roofing, and siding, and is also crucial for structural elements like beams and columns.

Electrical and Electronic Equipment

Aluminum, renowned for its superb electrical conductivity, finds extensive use in crafting electrical wiring, power transmission lines, and heat sinks for electronic devices.

Machinery and Equipment

Aluminum finds its way into the creation of diverse machinery and equipment, spanning industrial machines, agricultural tools, and everyday household appliances.

Consumer Goods

Aluminum plays a key role in crafting a diverse array of consumer products, from furniture and sporting equipment to musical instruments. Its lightweight nature, durability, and visual appeal make it a highly valued material.

The Potential Future of Aluminum

The future of aluminum is set to be marked by thrilling advancements and innovations. With a growing global emphasis on sustainability and environmental responsibility, aluminum is anticipated to be at the forefront of these efforts. We can expect significant strides in enhancing the efficiency and eco-friendliness of aluminum production, from refining methods to reducing energy use. Recycling technologies are also likely to evolve, boosting recycling rates and improving the quality of recycled aluminum. Additionally, ongoing alloy innovations will aim to develop materials with enhanced strength, corrosion resistance, and formability, aligning with the changing demands of various industries. We anticipate that lightweighting will continue to be a major trend, with aluminum taking the place of heavier materials in transportation. This shift will lead to better fuel efficiency and lower emissions. In construction, aluminum’s strengths—its durability, recyclability, and sleek appearance—will make it a go-to choice for sustainable buildings and infrastructure. As we move forward, aluminum’s role in new technologies, such as electric vehicles, renewable energy, and advanced electronics, is expected to grow. Digital and additive manufacturing techniques will further revolutionize aluminum production, allowing for intricate designs with less waste. In essence, aluminum’s future seems poised to be defined by sustainability, innovation, and its crucial part in advancing a greener, more tech-driven world.

Choosing the Right Aluminum Manufacturer

To achieve the best results when buying aluminum from a manufacturer, compare several companies using our directory. Each manufacturer’s business profile page showcases their expertise and capabilities, and includes a contact form for inquiries or quotes. Use our patented website previewer to swiftly understand each company’s specializations. Then, streamline your process by using our RFQ form to reach out to multiple aluminum companies with a single request.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services