Time is money, and we save you both. We don’t mess around when it comes to precious time, and we offer the highest quality aluminum products that other companies don’t stock. We make a point of keeping products on-hand that other companies will not, because it is our goal to make your experience with us painless and fulfilling. Visit our website or call us today to learn more!

At CBC Specialty Metals & Processing, we pride ourselves on being a leading provider of high-quality aluminum products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in aluminum distribution and processing, renowned for our commitment to excellence,...

Since 1923, EMJ has been a leading supplier of Steel and Aluminum Bar, Tubing, and Plate to manufacturing companies in North America. Our broad network of facilities, superior inventories, processing capabilities, and world-class technology enables EMJ to provide unsurpassed service to our customers.

At Triple-S Steel Holdings, Inc., we take pride in our position as a leading provider of high-quality aluminum products and comprehensive solutions tailored to meet the diverse needs of our clientele. With decades of experience and dedication to excellence, we have established ourselves as a trusted name in the aluminum industry, renowned for our commitment to quality, reliability, and customer...

More 7075 Aluminum Manufacturers

The 7075 aluminum alloy series has a composition that gives it a maximum strength to the point that it can hold its own against many steels. Although this is one of its most enticing qualities, it is the combination of this trait in combination with its other excellent features —low density, excellent machinability, and excellent corrosion resistance— that makes it the ideal candidate for highly-stressed structural parts. It is incredibly robust since zinc serves as its main alloying component.

Although it has a high strength, it does not offer the same levels of machinability or weldability as other typical aluminum alloys, however. Additionally, 7075 aluminum has a lower level of corrosion resistance than other aluminum alloys.

How 7075 Aluminum is Processed

How do we get products made from the 7075 aluminum alloy? Well, it’s a multistep process. First, the 7075 alloy needs to be created. This process involves combining aluminum together with a variety of other materials- most notably zinc due to the properties it provides this alloy (magnesium, copper, iron, and silicon are among the other ingredients found). Like other alloys, the ingredients of this alloy are melted down, mixed together, then allowed to cool into a solid form. From there, the alloy is then direct cast (DC).

Direct casting is a vertical semi-continuous casting technique. The procedure involves melting the now-alloyed material and pouring this molten melt onto a starting block, where the difference in temperatures causes the part of the melted material to solidify right away (direct chill). To enlarge the mushy zone (semi-solid zone), which will help the production of the end product, the solid material, is shifted downward. A water film continuously cools the mold walls. Only 20% of the heat is removed by heat transfer through the mold wall; the majority of heat (around 80%) is removed by direct cold.

The fundamental advantage of DC casting is the comparatively limited layer of solidification (and the production of structure and flaws) that occurs in a billet and can be tightly controlled. Typically, this alloy is cast into the form of solid ingots (blocks or bars). From there, these ingots are further processed through various processes (rolling, additional forging, etc.) into more workable forms, like sheets.

Advantages of 7075 Aluminum

- Among the numerous commonly-used aluminum alloys, 7075 aluminum has the distinction of being the strongest grade aluminum alloy for a variety of industrial applications. It provides a level of strength comparable to many steel alloys while also offering the advantages of being a lightweight metal, easily machinable, and corrosion resistant.

- Due to its reflecting quality and visually pleasing surface when polished, 7075 alloy frequently removes the need for painting while simultaneously lowering the object's weight, which is crucial for aerospace applications.

- The composition of 7075 aluminum is 90 percent aluminum, 5.6% zinc, 2.5% magnesium, and 1.6% copper, and it has a density of.102 pounds per cubic inch. It is the best choice for many structural parts of airplanes because it can withstand stresses brought on by high-altitude flights.

- T7351 and T173 tempers of the aluminum alloy 7075 offer outstanding stress corrosion resistance.

- As previously mentioned, zinc serves as the main alloying component of 7075 aluminum. The addition of chromium to an Al-Zn-Mg-Cu high-strength alloy for the first time gave 7075 an outstanding level of resistance to stress corrosion cracking in sheet form. In spite of its inability to be welded, middling performance, and negligible corrosion resistance, 7075 aluminum has a high level of fatigue strength. However, the alloy's high strength to density ratio makes it perfect for applications such as rock climbing and military weaponry, to mention a few.

Applications of 7075 Aluminum

Manufacturers and product consumers agree that the lightweight and durability properties of 7075 aluminum are very advantageous. Below, we examine some applications of 7075 aluminum.

- This aluminum alloy is used in the aerospace, aircraft, and automotive industries because of its outstanding fatigue resistance, which is very useful in these aforementioned sectors. For applications involving specific stresses like constant movement and pressure variations, this aluminum alloy is the most affordable choice.

- 7075 is widely employed in the creation of structures connected to airplanes, such as wings and fuselages. The 7075 aluminum alloy is used for a variety of components in other industries, including those involving recreation such as bicycle parts, rock climbing gear, archery equipment, and gun manufacturing. The 7075 aluminum alloy has been utilized in the M-16 rifles produced for the military.

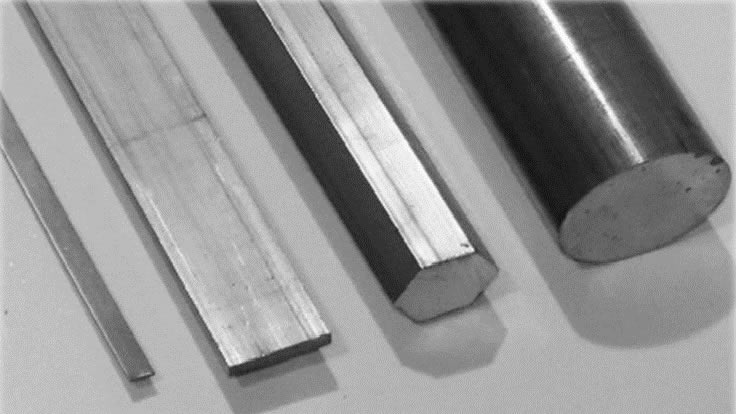

- To satisfy the requirements of varied applications, aluminum alloy 7075 is supplied in a variety of shapes. This alloy is particularly useful for high stress applications. Whether the application calls for plastic industry molds, military-grade guns, or bicycle parts, 7075 is frequently the alloy of choice. The 7075 aluminum alloy is also used to create gears, fuse parts, and other highly-stressed structural components.

Choosing the Correct 7075 Aluminum Supplier

To make sure you have the most productive outcome when purchasing 7075 Aluminum from a 7075 Aluminum Manufacturer, it is important to compare at least 4 or 5 Manufacturers using our list of 7075 Aluminum manufacturers. Each 7075 Aluminum Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each 7075 Aluminum company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple 7075 Aluminum companies with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services