Superior Alloy Technology Inc.

Superior Alloy Technology Inc.Request A Quote

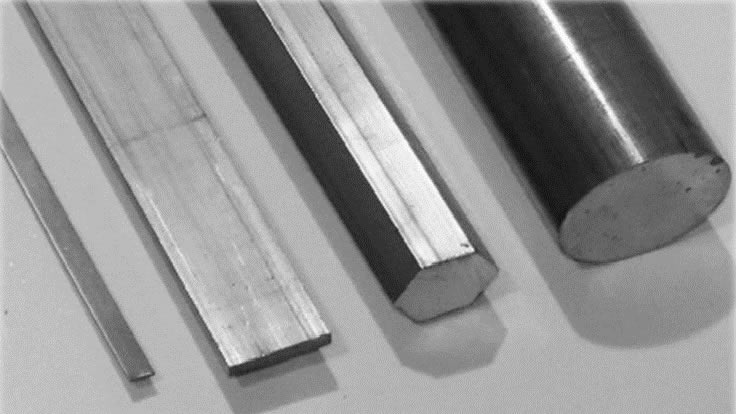

Boucherville, QC | 877-645-1119Superior Alloy Technology Inc. is a leading aluminum manufacturing company headquartered in Boucherville, Quebec, dedicated to delivering high-quality aluminum products and unparalleled service to a diverse range of industries. Established in 1995, the company has built a sterling reputation for its commitment to innovation, precision, and customer satisfaction. Location: Situated in the industrial hub of Boucherville, QC, Superior Alloy Technology Inc. operates from a state-of-the-art facility that spans over 50,000 square feet. The strategic location allows for efficient logistics and distribution, ensuring prompt and reliable delivery to clients across North America. Core Competencies: Aluminum Extrusion: Superior Alloy Technology specializes in aluminum extrusion, utilizing cutting-edge technology to transform raw aluminum into customized profiles for various applications. The company's extrusion capabilities cover a broad spectrum of shapes and sizes, meeting the diverse needs of industries such as construction, automotive, aerospace, and electronics. Alloy Expertise: With a team of skilled metallurgists and engineers, Superior Alloy Technology excels in developing aluminum alloys tailored to specific client requirements. This expertise allows the company to provide alloys with enhanced strength, durability, and corrosion resistance, ensuring optimal performance in challenging environments. Precision Machining: The company boasts an advanced machining division equipped with CNC machining centers, enabling the precise fabrication of aluminum components to tight tolerances. From simple to complex geometries, Superior Alloy Technology's machining capabilities add significant value to the finished products. Surface Finishing: Superior Alloy Technology understands the importance of aesthetics and protection in the final product. The company offers a range of surface finishing options, including anodizing, powder coating, and polishing, to enhance both the appearance and durability of aluminum products. Engineering and Design Support: Collaborating closely with clients, Superior Alloy Technology provides comprehensive engineering and design support throughout the product development process. This ensures that the final aluminum solutions align seamlessly with the client's specifications and industry standards. Quality Assurance: Committed to delivering excellence, Superior Alloy Technology employs rigorous quality control measures at every stage of production. The company adheres to international quality standards and certifications, guaranteeing the consistency and reliability of its aluminum products. Sustainability Initiatives: Superior Alloy Technology is dedicated to environmentally responsible manufacturing practices. The company actively invests in sustainable technologies and processes to minimize its carbon footprint and contribute to the industry's broader sustainability goals. Clientele: Superior Alloy Technology serves a diverse clientele, ranging from multinational corporations to small and medium-sized enterprises across various sectors. The company's commitment to quality, innovation, and customer satisfaction has fostered long-term partnerships with clients seeking cutting-edge aluminum solutions. In conclusion, Superior Alloy Technology Inc. stands at the forefront of the aluminum industry, combining decades of experience with a forward-thinking approach to deliver superior products and services that meet the evolving needs of its clients. Whether it's customized extrusions, precision machining, or alloy development, the company continues to set industry benchmarks for excellence.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services