SMC Metal Inc.

SMC Metal Inc.Request A Quote

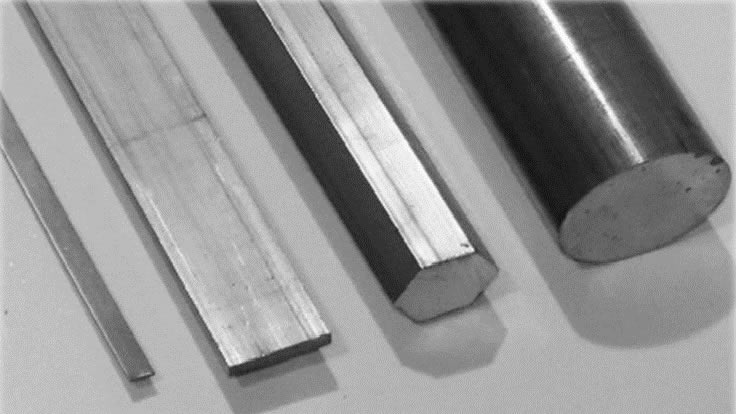

Fullerton, CASMC Metal Inc., headquartered in Fullerton, California, stands as a leading player in the metal industry, specializing in the production and distribution of high-quality aluminum products. With a commitment to innovation, quality, and customer satisfaction, SMC Metal Inc. has established itself as a trusted partner for various industries requiring top-notch aluminum solutions. Location: Situated in the industrial hub of Fullerton, SMC Metal Inc. benefits from a strategic location that facilitates efficient distribution and access to key markets. The state-of-the-art facilities are equipped with cutting-edge technology to ensure precision manufacturing and timely delivery. Core Competencies: Aluminum Extrusion: SMC Metal Inc. excels in aluminum extrusion, a process that transforms aluminum alloy into intricate and customized profiles. This capability allows the company to cater to diverse industries, including construction, automotive, aerospace, and electronics. Alloy Expertise: The company boasts extensive knowledge and expertise in working with various aluminum alloys, ensuring that the products meet specific performance, strength, and durability requirements. This adaptability makes SMC Metal Inc. a preferred choice for clients with unique specifications. Custom Solutions: SMC Metal Inc. understands that every project is unique. Therefore, the company offers tailored solutions to meet the precise needs of its clients. The in-house design and engineering teams collaborate closely with customers to create custom aluminum profiles that align with their project goals. Precision Machining: Beyond extrusion, SMC Metal Inc. provides precision machining services to further refine aluminum components. This includes cutting, milling, drilling, and finishing processes, ensuring that the final products meet the highest industry standards. Quality Assurance: Committed to delivering excellence, SMC Metal Inc. has implemented stringent quality control measures at every stage of production. Rigorous testing and inspection procedures guarantee that customers receive aluminum products that adhere to international quality standards. Environmental Responsibility: SMC Metal Inc. prioritizes sustainability in its operations. The company is dedicated to reducing its environmental footprint by implementing eco-friendly practices and utilizing recycled aluminum in its manufacturing processes whenever possible. Clientele: SMC Metal Inc. serves a diverse clientele, ranging from small businesses to large corporations. Its aluminum products find applications in construction projects, automotive manufacturing, aerospace technology, and electronic components, among others. Vision: Driven by a vision to be the preferred choice for aluminum solutions globally, SMC Metal Inc. continually invests in research and development, technological advancements, and employee training to stay at the forefront of the industry. In conclusion, SMC Metal Inc. is not merely a supplier of aluminum products; it is a partner in progress, offering innovative solutions, unparalleled quality, and a commitment to customer success. As the company looks to the future, it remains dedicated to pushing the boundaries of what's possible in the world of aluminum manufacturing.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services