Rickard Specialty Metals & Engineering

Rickard Specialty Metals & EngineeringRequest A Quote

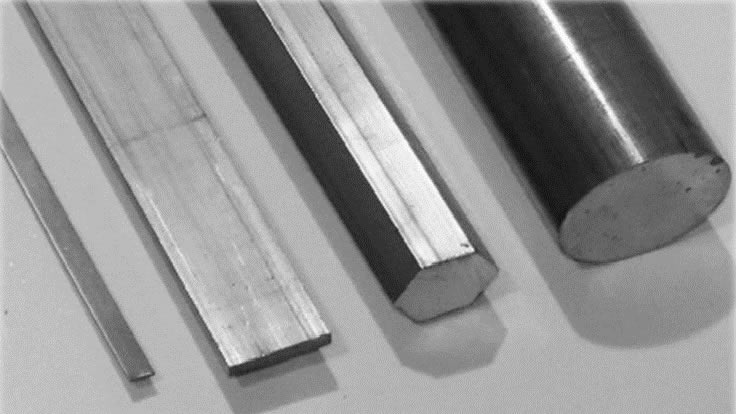

Ontario, CA | 800-966-4922Rickard Specialty Metals & Engineering is a leading provider of high-quality aluminum products and comprehensive engineering solutions, headquartered in Ontario, California. Established in [year of establishment], our company has garnered a reputation for excellence in the aluminum industry, offering a wide range of specialized products and services to meet the diverse needs of our clients. Location: Our strategically located facility in Ontario, CA, serves as the hub for our operations. Situated in the heart of one of the most industrially significant regions in the United States, we take pride in our accessible location that enables us to efficiently cater to the demands of clients nationwide. Core Competencies: 1. Aluminum Products: At Rickard Specialty Metals & Engineering, we specialize in the manufacturing and distribution of premium-grade aluminum products. Our extensive product portfolio includes aluminum sheets, plates, bars, rods, and custom extrusions. These products are crafted to meet the highest industry standards, ensuring durability, corrosion resistance, and optimal performance in various applications. 2. Engineering Expertise: Our team of skilled engineers and metallurgists are at the forefront of innovation, providing customized solutions to address the unique requirements of our clients. Whether it's designing specialized aluminum alloys or developing custom extrusions, our engineering capabilities enable us to deliver tailor-made solutions that exceed expectations. 3. Fabrication and Processing: In addition to supplying raw aluminum materials, Rickard Specialty Metals & Engineering offers comprehensive fabrication and processing services. Our state-of-the-art facility is equipped with cutting-edge machinery and technology, allowing us to provide precision cutting, CNC machining, heat treatment, and other value-added processes. 4. Quality Assurance: Quality is at the core of our operations. We adhere to rigorous quality control standards throughout the production process to ensure that our aluminum products meet or exceed industry specifications. Our commitment to quality is backed by certifications and compliance with industry regulations. Customer-Centric Approach: At Rickard Specialty Metals & Engineering, we prioritize customer satisfaction. Our dedicated team works closely with clients to understand their specific needs and challenges, offering personalized solutions that add significant value to their projects. Timely delivery, competitive pricing, and unmatched customer support are the pillars of our customer-centric approach. Sustainability Commitment: Recognizing the importance of environmental responsibility, we are committed to sustainable practices in our operations. From responsible sourcing of raw materials to energy-efficient production processes, we strive to minimize our environmental impact while delivering top-notch products. Conclusion: Rickard Specialty Metals & Engineering stands as a reliable partner for businesses seeking high-quality aluminum products and engineering solutions. With a commitment to excellence, innovation, and customer satisfaction, we look forward to contributing to the success of our clients across diverse industries.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services