Howard Precision Metals Inc.

Howard Precision Metals Inc.Request A Quote

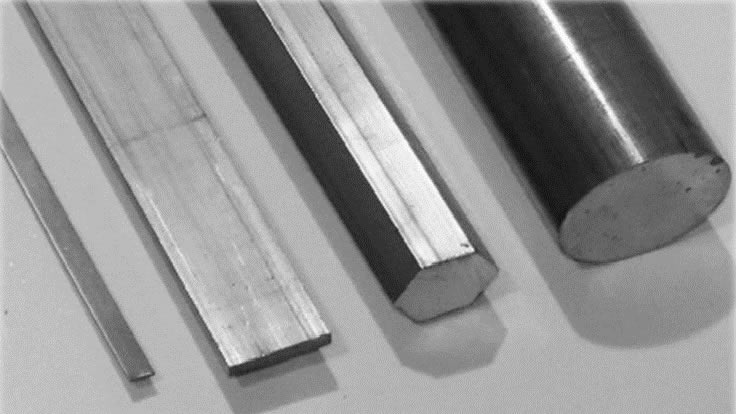

Milwaukee, WIHoward Precision Metals Inc., headquartered in Milwaukee, Wisconsin, stands as a distinguished leader in the field of aluminum distribution and processing. With a rich history dating back to its establishment, the company has continuously evolved, solidifying its reputation as a reliable and innovative partner in the aluminum industry. Specializing in precision-cut aluminum products, Howard Precision Metals is committed to delivering top-tier solutions that meet the diverse needs of its clientele. Location: Situated in the industrial heartland of Milwaukee, Wisconsin, Howard Precision Metals strategically positions itself at the crossroads of manufacturing and innovation. The central location not only ensures efficient distribution across the United States but also facilitates easy access to key transportation networks, fostering seamless logistical operations. Core Competencies: Aluminum Distribution: Howard Precision Metals prides itself on being a premier distributor of aluminum products. The company maintains a vast inventory of high-quality aluminum sheets, plates, and extrusions sourced from reputable mills. This comprehensive selection allows them to serve industries ranging from aerospace and automotive to electronics and construction. Precision Cutting and Processing: The company's core strength lies in its precision cutting and processing capabilities. Equipped with state-of-the-art machinery and a team of skilled technicians, Howard Precision Metals excels in providing custom solutions tailored to exact specifications. Whether it's intricate shapes, tight tolerances, or specific alloys, the company has the expertise to deliver precision-cut aluminum products that meet the most demanding requirements. Quality Assurance: Committed to delivering excellence, Howard Precision Metals places a strong emphasis on quality assurance. Rigorous inspection processes are integrated into every stage of production, ensuring that each product adheres to the highest industry standards. This dedication to quality has earned the company the trust of clients who prioritize precision and reliability. Customer-Centric Approach: Howard Precision Metals places a premium on customer satisfaction. The company's customer-centric approach involves collaborating closely with clients to understand their unique needs and challenges. This personalized engagement allows Howard Precision Metals to offer tailored solutions, establishing long-lasting partnerships built on trust and mutual success. Innovation and Adaptability: In a rapidly evolving industry, Howard Precision Metals remains at the forefront of innovation. The company continually invests in research and development, staying abreast of the latest advancements in aluminum technology. This commitment to innovation enables Howard Precision Metals to offer cutting-edge solutions that address the evolving demands of various industries. Conclusion: In the realm of aluminum distribution and processing, Howard Precision Metals Inc. emerges as a reliable partner, blending a rich history with a commitment to quality, precision, and innovation. From its strategic location in Milwaukee, Wisconsin, the company serves as a vital link in the supply chain, providing top-notch aluminum products and solutions that empower industries to thrive and succeed in an ever-changing marketplace.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services