ESPI Metals

ESPI MetalsRequest A Quote

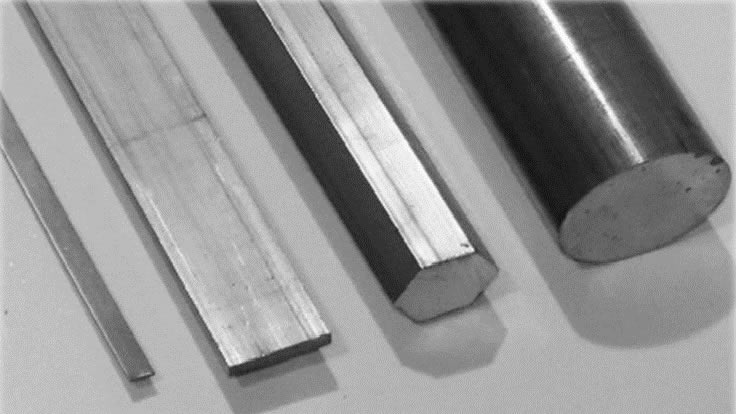

Ashland, ORESPI Metals, headquartered in Ashland, Oregon, stands as a leading provider of high-quality aluminum products and services. With a commitment to precision, innovation, and customer satisfaction, ESPI Metals has emerged as a trusted name in the metals industry. Situated in the picturesque city of Ashland, ESPI Metals benefits from a strategic location that not only reflects the company's commitment to sustainability but also provides easy access to transportation networks. This enables the seamless distribution of their aluminum products to customers across diverse industries. Recognizing the evolving needs of their clients, ESPI Metals boasts a team of experienced metallurgists and engineers capable of developing custom aluminum alloys. This capability allows the company to offer tailor-made solutions to industries with specific material requirements, ensuring optimal performance in their applications. Quality is at the forefront of ESPI Metals' operations. The company adheres to rigorous quality control measures throughout the manufacturing process, ensuring that their aluminum products consistently meet or exceed industry standards. This commitment to quality has earned ESPI Metals a reputation for reliability and excellence among their clientele. ESPI Metals stands as a beacon of excellence in the aluminum industry. With a focus on quality, innovation, and sustainability, the company continues to provide cutting-edge solutions and services to industries requiring high-performance aluminum products. ESPI Metals' commitment to customer satisfaction, precision machining, and custom alloy development positions them as a reliable partner for clients seeking top-tier aluminum solutions.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services