BRC Engineering Inc.

BRC Engineering Inc.Request A Quote

Armada, MIBRC Engineering Inc. stands as a pioneering force in the heart of Armada, Michigan, seamlessly blending innovation, precision, and expertise to deliver unparalleled aluminum products and service solutions. Established with a commitment to excellence, BRC Engineering has emerged as a trusted name, redefining industry standards through its cutting-edge engineering and manufacturing capabilities. Mission: At the core of BRC Engineering Inc.'s ethos is the mission to provide top-notch aluminum products and services, meeting and exceeding the dynamic needs of diverse industries. Our mission is to consistently push the boundaries of innovation, ensuring that our clients receive solutions that are not only of the highest quality but also tailored to their specific requirements. Core Competencies: Aluminum Expertise: BRC Engineering specializes in the utilization of aluminum, showcasing a deep understanding of its unique properties and applications. From precision machining to intricate fabrication, our team of skilled engineers and technicians possess the expertise to transform raw aluminum materials into high-performance components. Engineering Excellence: Our commitment to engineering excellence is evident in every project we undertake. BRC Engineering boasts a state-of-the-art facility equipped with advanced technologies, enabling us to conceptualize, design, and produce intricate aluminum products with precision and efficiency. Custom Solutions: Recognizing the diverse needs of our clientele, BRC Engineering excels in providing custom solutions. Whether it's a complex aerospace component, automotive part, or architectural element, our team collaborates closely with clients to understand their unique specifications and deliver tailor-made solutions that meet or exceed expectations. Quality Assurance: Quality is at the forefront of everything we do. BRC Engineering adheres to rigorous quality control measures throughout the production process to ensure that each aluminum product meets the highest industry standards. Our commitment to quality extends to post-production testing and inspection, guaranteeing the reliability and durability of our offerings. Client-Centric Approach: BRC Engineering prioritizes client satisfaction, fostering collaborative relationships built on transparency, communication, and trust. Our team works closely with clients from project initiation to completion, providing regular updates and ensuring that their unique needs are met with precision. Industries Served: BRC Engineering caters to a diverse range of industries, including aerospace, automotive, construction, and more. Our ability to adapt and tailor our services to different sectors underscores our versatility and underscores our commitment to being an industry leader. Facility and Technology: Situated in Armada, Michigan, our cutting-edge facility is equipped with the latest technologies and machinery. This ensures that we stay at the forefront of industry advancements, allowing us to consistently deliver aluminum products that meet the evolving demands of the market. In summary, BRC Engineering Inc. stands as a beacon of excellence in the realm of aluminum engineering. Our commitment to quality, innovation, and client satisfaction propels us forward, positioning us as a preferred partner for those seeking superior aluminum products and service capabilities.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

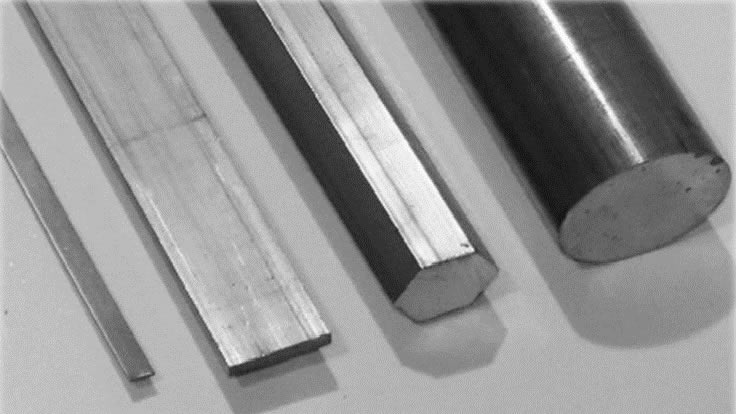

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services