Accro-Met, Inc.

Accro-Met, Inc.Request A Quote

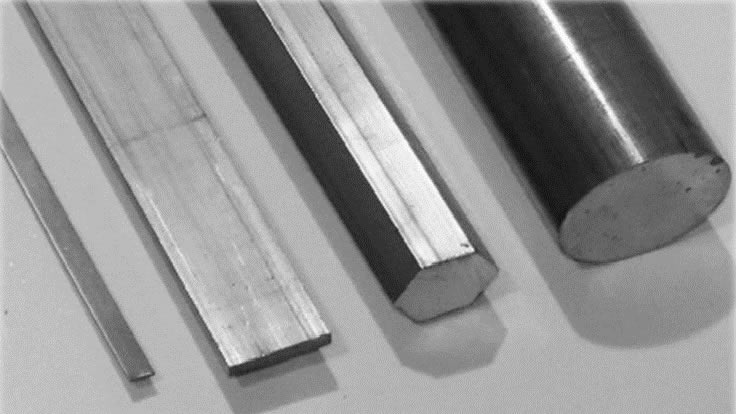

Monroe, NC | 800-543-4755Accro-Met, Inc. stands as a distinguished industry leader in Monroe, NC, specializing in the production and distribution of high-quality aluminum products. With a commitment to excellence, innovation, and customer satisfaction, Accro-Met has established itself as a reliable partner for a wide range of industries that rely on top-notch aluminum solutions. Core Competencies: Aluminum Manufacturing: Accro-Met boasts state-of-the-art manufacturing facilities dedicated to the production of aluminum products. The company is equipped with cutting-edge technology and employs a team of skilled professionals who ensure precision in every stage of the manufacturing process. From casting to finishing, Accro-Met maintains stringent quality control measures to deliver products that meet or exceed industry standards. Product Portfolio: The company's diverse product portfolio encompasses a wide range of aluminum components and materials. This includes aluminum sheets, extrusions, coils, and custom-designed profiles tailored to the specific needs of clients. Whether clients are in the aerospace, automotive, construction, or electronics industries, Accro-Met offers aluminum solutions that align with the highest performance and quality requirements. Customization Capabilities: Accro-Met takes pride in its ability to provide customized aluminum solutions. The company collaborates closely with clients to understand their unique specifications and design requirements. Through advanced engineering and a flexible manufacturing process, Accro-Met delivers bespoke aluminum products that cater to the distinct needs of individual projects. Research and Development: Committed to staying at the forefront of aluminum technology, Accro-Met invests in ongoing research and development initiatives. This commitment allows the company to introduce cutting-edge products, improve existing processes, and adapt to emerging industry trends. Clients benefit from Accro-Met's dedication to innovation, ensuring they receive aluminum products that reflect the latest advancements in the field. Environmental Responsibility: Accro-Met is conscious of its environmental impact and is committed to sustainable practices. The company incorporates eco-friendly processes in its manufacturing and waste management, adhering to industry best practices to minimize its carbon footprint. This commitment to environmental responsibility aligns with Accro-Met's dedication to corporate social responsibility. Client Focus: Accro-Met's client-centric approach is evident in its commitment to delivering products on time and within budget. The company prioritizes building long-term relationships by providing excellent customer service, technical support, and after-sales assistance. This client focus has earned Accro-Met a reputation for reliability and trustworthiness in the aluminum manufacturing industry. Conclusion: Accro-Met, Inc. in Monroe, NC, stands as a beacon of excellence in the aluminum manufacturing sector. Through a combination of cutting-edge technology, customization capabilities, research and development initiatives, and a strong commitment to environmental responsibility, Accro-Met continues to be a preferred partner for businesses seeking top-quality aluminum products and services.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services