Time is money, and we save you both. We don’t mess around when it comes to precious time, and we offer the highest quality aluminum products that other companies don’t stock. We make a point of keeping products on-hand that other companies will not, because it is our goal to make your experience with us painless and fulfilling. Visit our website or call us today to learn more!

With global distribution operations covering North America, Europe, the Middle East and Asia, MTS has your material needs covered. Specializing in providing stock and custom materials such as aluminum—1100, 6061, 7075, plate, bar, coil, pipe, sheet & more—to aerospace, high tech, transportation, chemicals & pharmaceuticals processing, medical equipment, marine and general engineering...

At Murphy and Nolan Inc., we take pride in crafting high-quality aluminum products that meet the diverse needs of our customers. With a rich history spanning several decades, our commitment to excellence has solidified our position as a trusted provider in the industry.

Future Alloys is an independently owned and operated aluminum service center established in 1982. All of our dedicated employees operate with the goal of meeting or exceeding our customer’s expectations. Our 34,000 square foot facility holds an extensive inventory of mill certified aluminum bar, plate, sheet and rod in numerous aluminum alloys, such as 7075 and 6061, to meet your specific needs.

Send Requests For Quote to Multiple Aluminum Suppliers Near You

Provide your project details, and we'll connect you to 5-20 qualified aluminum companies in your region. 100% free.

Get InformationManually Sourcing U.S./Canadian Manufacturers for 20+ Years

More Aluminum Sheet Manufacturers

Aluminum sheets are created by forcing this metal into a thinner, longer shape while passing it through high-pressure rollers. In addition to being inherently simple to install and maintain, aluminum sheeting is typically made to be extremely thin, lightweight, and robust enough to provide extreme adaptability.

Aluminum sheets have numerous uses. They also have a wide range of additional distinctive and advantageous qualities that make them used very frequently in a large number of industrial and agricultural applications today.

Types of Aluminum Sheets

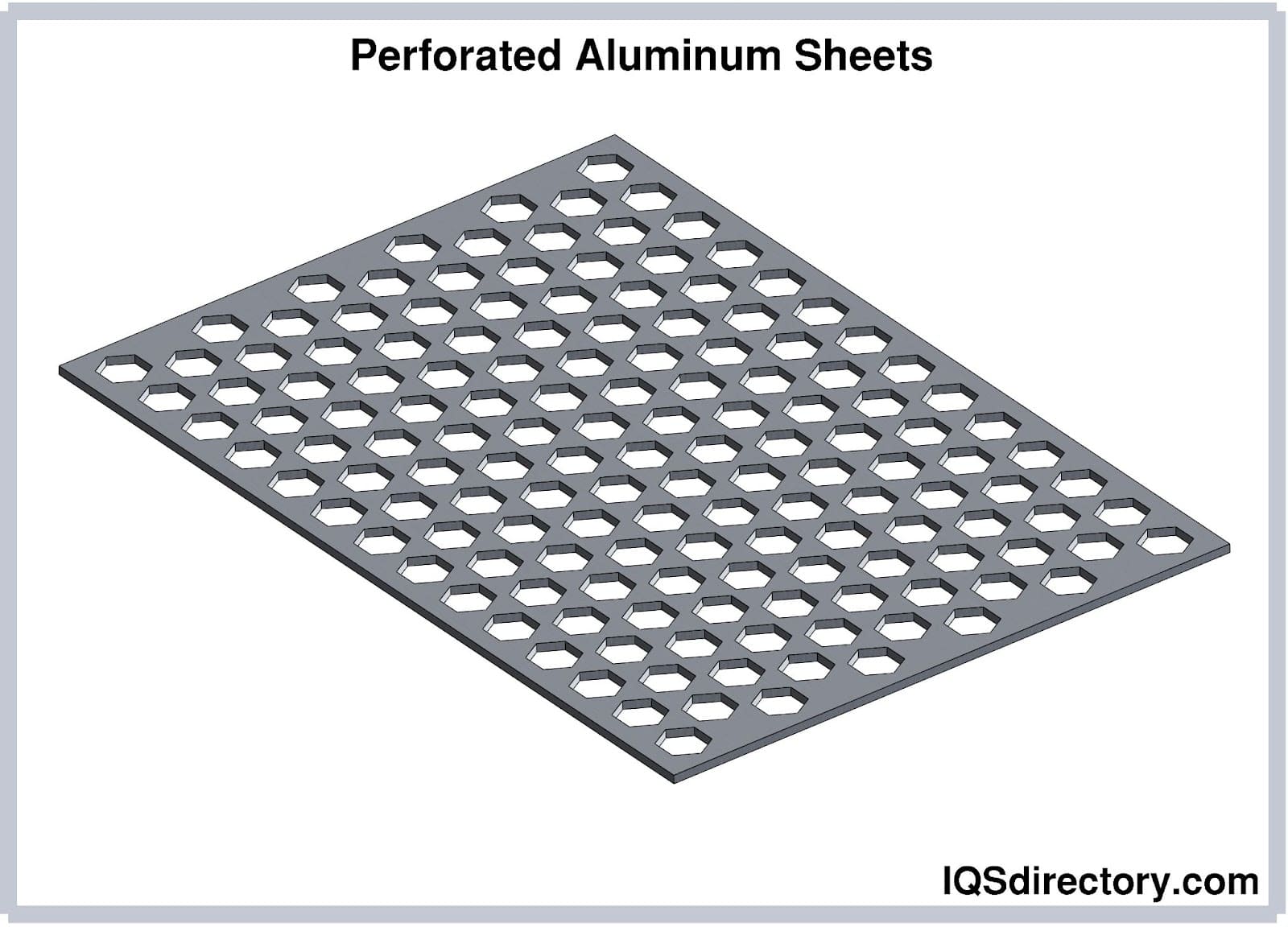

Perforated

Round, square, slotted, and decorative-shaped hole patterns are available on a variety of perforated aluminum sheets. Perforated aluminum sheets are typically employed in situations where it is picked primarily for aesthetic reasons. This occurs frequently in interior and outdoor design projects, such as when building various types of flooring, ceilings, screens, blinds, and decorative panels. Other common uses could be in the food industry, factories, or laboratories. In these settings, it is frequently used in industrial washing and drying stations to conduct rinsing, drainage, and collection functions.

Composite

An aluminum composite panel is created by sandwiching a thermoplastic polyethylene core between two flat external aluminum panels to create a sheet that is stiff, flat, smooth, and lightweight, but also sturdy and long-lasting. They are often used in multiple insulation and folding panel applications, as well as being utilized as thin, sturdy panels for building facades or exterior cladding. Aluminum composite panel sheets are much lighter than their solid metal counterparts.

Anodized

The oxide coating on the surface of metals is thickened through an electrochemical process called anodizing. Anodized aluminum sheets have higher corrosion resistance than other types of aluminum sheets. Anodized metals are typically represented by highly-colored aluminum sheets or other decorative panels, such as those frequently used in vehicles, smartphones, tools, cookware, sporting goods, and architectural materials.

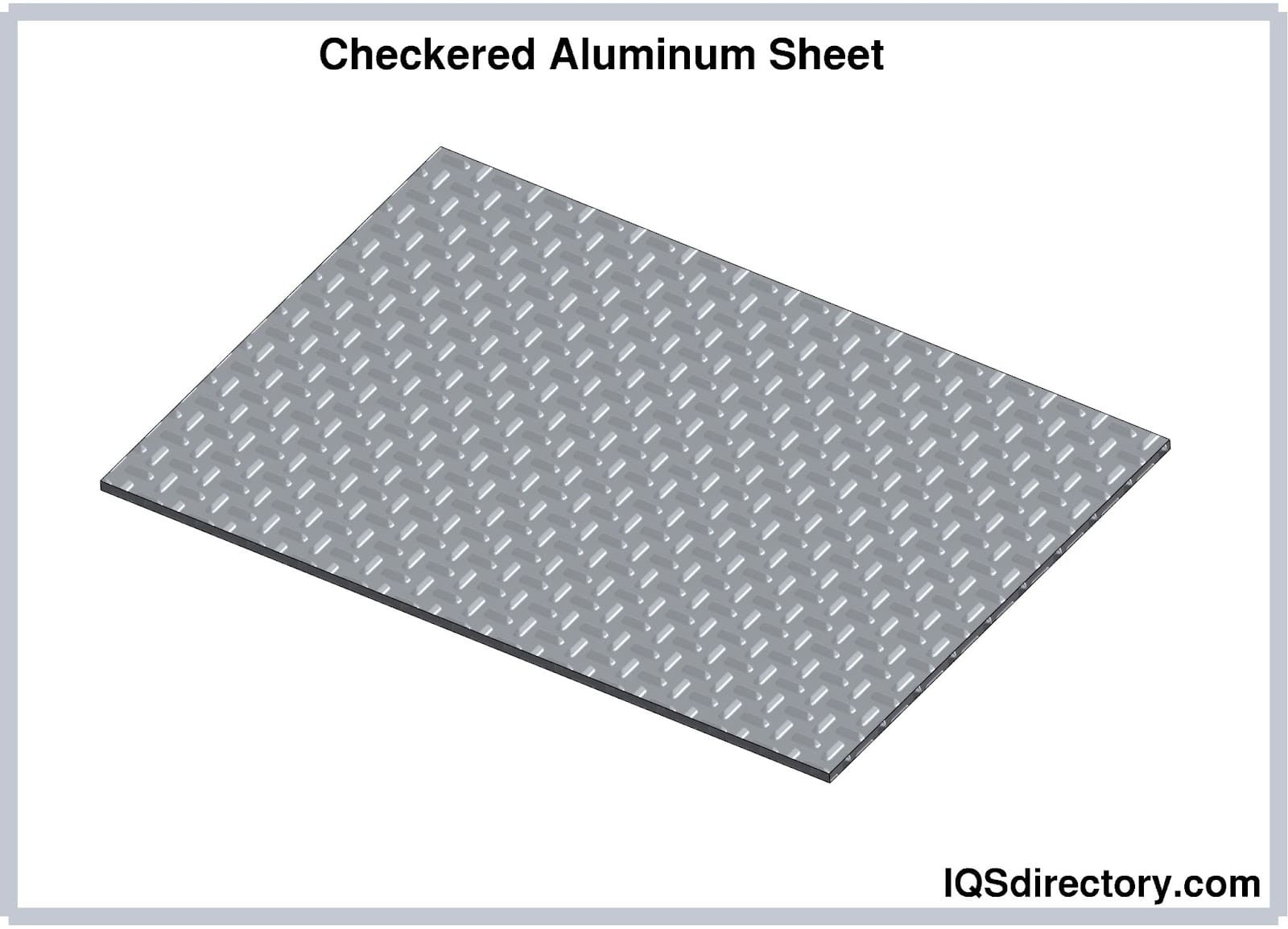

Checkered

Aluminum checkered plates are metal sheets that have heightened hatch markings on one side, creating a raised pattern. Since they are moderately thick and robust sheets with superior impact resistance and load-bearing capabilities, they are suitable for use in interior or outdoor areas with significant foot traffic and heavy vehicles, such as service hallways, loading bays, and parking lots. In addition to providing extra traction to avoid slides and skids, the embossed pattern conceals surface imperfections.

Brushed Aluminum Sheets

Anodized and composite panels are only two examples of the several types of aluminum sheeting that are offered in both brushed and unbrushed versions. In this usage, the term "brushed" describes a purposeful application of light parallel scratches and scuffs across the surface of a metal sheet to create a satin-like appearance. The impact can be seen clearly on a variety of interior fixtures and fittings. Purchasing brushed aluminum sheet is frequently primarily an aesthetic choice.

Applications and Benefits of Aluminum Sheets

- The food and beverage industry frequently uses aluminum sheets for packaging. Aluminum is the perfect metal for cans since it is malleable and makes manufacturing easier. Both food and thinner, lighter drink cans are made from them. The fact that aluminum does not rust is just one of the many benefits of using it for food and beverage packaging. Aluminum is suitable for food packaging because it is also odorless.

- Aluminum sheeting is frequently used in car bodywork and paneling construction. Owing to its lighter weight than steel, aluminum has grown in popularity in the production of modern automobiles. Each pound of aluminum used in an automobile reduces the overall weight by one pound when compared to the steel traditionally found in automobiles.

- Aluminum is a common material for a variety of home appliances, such as washing machines, dryers, and refrigerators, due to its comparatively light weight, structural strength, electrical, and thermal properties. A lot of gadgets, including phones and laptops, are built with aluminum. The thermal conductivity of aluminum, which makes cooling easier and ensures extremely efficient refrigeration, revolutionized the modern refrigerator.

- Numerous uses for aluminum sheets can be found in the building and housing sectors. Gutters, siding, roofing, and cladding are just a few of the various applications for aluminum. Aluminum is the second most common metal used in construction, after steel.

- The superstructures of ships make substantial use of aluminum plate and extrusions. The use of these materials enables designers to enhance the vessel's above-water dimensions without compromising stability. Aluminum has allowed maritime architects to design hovercraft, swift multi-hulled catamarans, and planing-surface vessels with superior performance from the available power provided by aluminum’s lighter weight.

- Commercial foils made of aluminum can be as thin as 0.63 mils (and a mil equals 1/1000”). Light, gasses, oils and fats, volatile chemicals, and water vapor cannot pass through aluminum foil. Aluminum foil is utilized in a variety of applications due to its high formability, heat and cold resistance, non-toxicity, strength, and heat and light reflection. These foils can be utilized in laminates and pharmaceutical applications.

- Aluminum is completely recyclable and keeps all of its original characteristics throughout the recycling process.

Choosing the Right Aluminum Sheets Supplier

To make sure you have the most beneficial outcome when purchasing Aluminum Sheets from an Aluminum Sheets Supplier, it is important to compare at least 5 or 6 Companies using our list of Aluminum Sheets companies. Each Aluminum Sheets Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Aluminum Sheets company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Aluminum Sheets companies with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services